In modern feed production, precision and efficiency are essential for operational success. FAMSUN’s feed grinding machine offers advanced solutions that meet diverse grinding requirements while maintaining high performance. They focus on delivering machinery that ensures consistent particle size, operational reliability, and adaptability across various feed types.

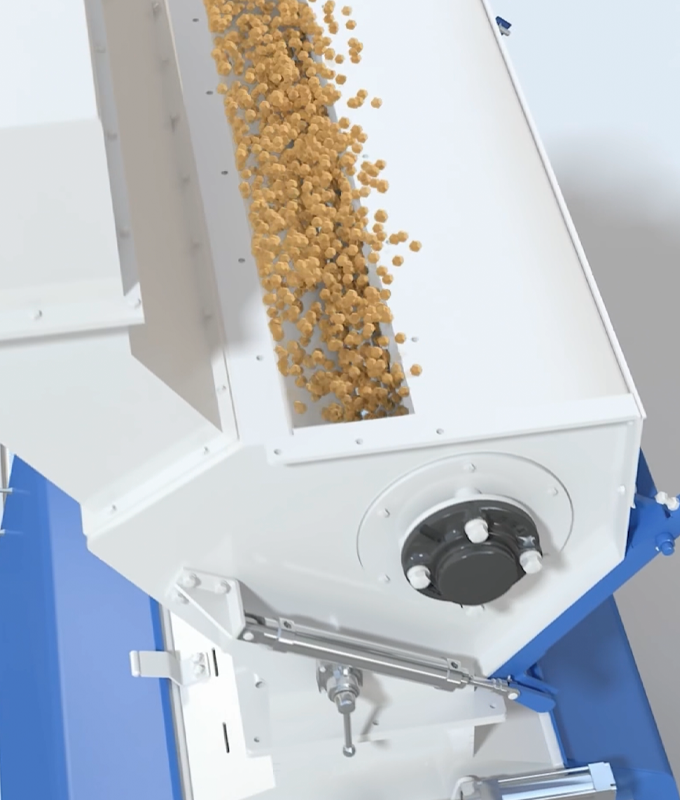

SWFP66 Series Hammer Mill: Versatile and Efficient

They highlight the SWFP66 Series Hammer Mill as a cornerstone of their feed grinding machine lineup. With nearly 50 years of experience in hammer mill design, they provide equipment capable of coarse grinding for pig, poultry, and ruminant feed, as well as fine grinding for aqua feed and pet food. Additionally, it supports pre-grinding of grain. The material-blocking structure in the grinding chamber disrupts the recirculation layer, significantly improving grinding efficiency, while the optimized chamber design maximizes screen opening, enhancing overall performance.

Precision Grinding for Consistent Quality

FAMSUN’s feed grinding machine emphasizes precise particle size control, ensuring uniform output that enhances feed digestibility and quality. They design machinery to adapt to different raw materials, providing flexibility for manufacturers handling multiple feed types. By combining robust construction with industry-leading engineering, they ensure long-term operational reliability, low maintenance, and high efficiency, enabling customers to maintain smooth and productive feed processing lines.

Conclusion

Overall, FAMSUN’s feed grinding machine demonstrates how advanced engineering supports modern feed processing. They deliver versatile, high-efficiency solutions capable of handling diverse feed types while ensuring precise particle size and consistent output. By prioritizing adaptability, reliability, and efficiency, they provide customers with equipment that maximizes productivity and reinforces FAMSUN’s position as a trusted partner in feed processing technology.